Innovations in Sustainable Fashion:

How Technology Is Reshaping Clothing Manufacturing

.

AYA | MARCH 21, 2025

READING TIME: 6 minutes

By Jordy Munarriz & Lesia Tello

AYA | MARCH 21, 2025

READING TIME: 6 minutes

By Lesia Tello & Jordy Munarriz

The Role of Innovation in Sustainable Fashion

The fashion industry is undergoing a technological revolution driven by sustainability and efficiency. As environmental concerns rise, manufacturers are increasingly adopting automated, digitalized, and eco-conscious solutions to minimize waste, reduce energy consumption, and promote ethical practices. From advanced fiber recycling technologies to robotic garment assembly, innovation is reshaping the way textiles are produced, dyed, and distributed. But are these technologies enough to transform an industry built on overproduction and disposable trends?

Industry 4.0 and Automation in Textile Manufacturing

Industry 4.0 is ushering in a new era of smart manufacturing, where artificial intelligence (AI), automation, and data-driven decision-making improve efficiency and sustainability. The integration of IoT (Internet of Things), machine learning, and real-time monitoring systems helps manufacturers optimize processes and reduce resource waste [1,2].

Robotics and AI are revolutionizing garment production by improving precision, reducing fabric waste, and increasing production speed. Automated sewing machines enhance efficiency, while AI-driven material selection predicts consumer preferences, reducing overproduction and textile waste. Major brands such as Adidas and Nike have implemented robotics in their production lines to optimize efficiency [1]. Additionally, RFID (Radio Frequency Identification) tags and blockchain technology are being leveraged to improve supply chain transparency. RFID tags allow real-time tracking of textiles, preventing overstock and unnecessary production, while blockchain provides immutable tracking of sustainable materials and ethical labor conditions. Companies like Prada and Stella McCartney have integrated blockchain systems to verify ethical sourcing and ensure responsible manufacturing [3,4].

AI Automation in Textile Manufacturing

Advanced Eco-Friendly Textile Processing Techniques

Traditional textile processing is resource-intensive, involving high water and chemical usage. Recent innovations focus on reducing the environmental footprint of textile manufacturing through enzyme-based finishing, biodegradable fibers, and digital printing [2,4].

Lyocell, a fiber derived from wood pulp, is produced through a closed-loop process where 99% of the non-toxic solvents are recycled. This sustainable alternative to conventional fabrics is used by brands such as Patagonia and Stella McCartney as a replacement for conventional cotton and synthetic fibers [1].

Enzyme applications in textile processing are replacing chemical treatments with bio-engineered enzymes, which reduce water pollution and energy consumption. Enzymes such as amylases, cellulases, and pectinases assist in bio-finishing, bio-polishing, and stain removal, eliminating the need for harsh chemicals. Companies like Novozymes and DuPont Industrial Biosciences specialize in enzyme-based textile treatments, making the industry more environmentally responsible [2].

Digital textile printing is another significant advancement, eliminating toxic chemicals used in traditional screen printing. This technology saves up to 90% of printing costs and reduces water consumption by 50%. Leading companies such as Kornit Digital and Epson are pioneers in waterless digital textile printing, offering a sustainable solution for mass customization [4].

Sustainable Digital Textile Printing

Sustainable Fabric Treatment and Textile Innovation

Beyond fiber selection, sustainable innovation extends to treatment and material development. Emerging advancements are pushing the boundaries of sustainability, replacing outdated practices with regenerative alternatives [2].

Microbial textile dyeing is an innovative approach that replaces synthetic dyes with bacteria-based pigments. This method eliminates toxic dye waste, reduces water consumption, and lowers the overall environmental impact of textile coloring. Companies like Colorifix are pioneering bioengineered dyeing solutions that promise to revolutionize the fashion industry by replacing petroleum-based dyes with naturally occurring pigments [2,4].

Nanotechnology is also transforming textile performance and sustainability. Nano-enhanced fabrics offer water-repellency, stain resistance, and antibacterial properties without the use of harmful PFAS (per- and polyfluoroalkyl substances). Brands are exploring nanofiber coatings that enhance durability while reducing chemical exposure in textile treatments [1].

3D knitting is another disruptive innovation in sustainable fashion. Unlike traditional cut-and-sew manufacturing, 3D knitting produces garments in a single seamless piece, eliminating fabric waste. Companies like Unmade and Adidas are using this technology to create customizable, waste-free clothing, offering a revolutionary approach to sustainable garment production [2].

3D Knitting Machine for Sustainable Fashion

Changing Demographics and Preferences

The pandemic also highlighted shifting demographics in the fashion market. Younger consumers, particularly Gen Z and Millennials, became increasingly influential in shaping purchasing trends. Research from the Institute for Sustainable Fashion indicates that younger generations are more likely to support sustainable brands, with 83% of Millennials stating they prefer to buy from companies that share their values [7,8].

Moreover, with the rise of remote work, many consumers reported a preference for comfort over style. A study published in the Journal of Fashion Marketing and Management noted that comfort became the primary driver of clothing purchases for many consumers, with 65% prioritizing comfort in their buying decisions [9]. This trend is likely to persist as remote work becomes a more permanent aspect of many industries.

Changing Demographics and Preferences

The pandemic also highlighted shifting demographics in the fashion market. Younger consumers, particularly Gen Z and Millennials, became increasingly influential in shaping purchasing trends. Research from the Institute for Sustainable Fashion indicates that younger generations are more likely to support sustainable brands, with 83% of Millennials stating they prefer to buy from companies that share their values [7,8].

Moreover, with the rise of remote work, many consumers reported a preference for comfort over style. A study published in the Journal of Fashion Marketing and Management noted that comfort became the primary driver of clothing purchases for many consumers, with 65% prioritizing comfort in their buying decisions [9]. This trend is likely to persist as remote work becomes a more permanent aspect of many industries.

Changing Demographics and Preferences

The pandemic also highlighted shifting demographics in the fashion market. Younger consumers, particularly Gen Z and Millennials, became increasingly influential in shaping purchasing trends. Research from the Institute for Sustainable Fashion indicates that younger generations are more likely to support sustainable brands, with 83% of Millennials stating they prefer to buy from companies that share their values [7,8].

Moreover, with the rise of remote work, many consumers reported a preference for comfort over style. A study published in the Journal of Fashion Marketing and Management noted that comfort became the primary driver of clothing purchases for many consumers, with 65% prioritizing comfort in their buying decisions [9]. This trend is likely to persist as remote work becomes a more permanent aspect of many industries.

Changing Demographics and Preferences

The pandemic also highlighted shifting demographics in the fashion market. Younger consumers, particularly Gen Z and Millennials, became increasingly influential in shaping purchasing trends. Research from the Institute for Sustainable Fashion indicates that younger generations are more likely to support sustainable brands, with 83% of Millennials stating they prefer to buy from companies that share their values [7,8].

Moreover, with the rise of remote work, many consumers reported a preference for comfort over style. A study published in the Journal of Fashion Marketing and Management noted that comfort became the primary driver of clothing purchases for many consumers, with 65% prioritizing comfort in their buying decisions [9]. This trend is likely to persist as remote work becomes a more permanent aspect of many industries.

The Future of Sustainable Fashion Manufacturing

These innovations are reshaping the textile industry by reducing its environmental footprint while increasing efficiency. However, challenges remain. The high costs of adoption prevent small-scale manufacturers from integrating new technologies. Consumer habits still drive demand for fast fashion, requiring an industry-wide shift in consumption behavior. Regulatory frameworks also need to enforce stronger environmental guidelines to push large corporations toward sustainable solutions [1,3].

The Road Ahead for Eco-Friendly Fashion

The future of fashion lies in technological innovation, automation, and circular economy models. Big companies leading the change, such as Nike, Patagonia, Adidas, and Unmade, are setting new standards for sustainable textile production. But to make a lasting impact, industry-wide adoption of these cutting-edge technologies is essential. As a consumer, your choices matter. Supporting brands that invest in sustainable innovations can drive demand for responsible manufacturing. The shift toward a fully circular, transparent, and low-impact fashion industry is not just possible—it’s necessary [1,2,4].

Glossarykeywords

3D Knitting:

A seamless garment production technique that eliminates fabric waste by directly knitting entire pieces, reducing material consumption and improving efficiency.

AI (Artificial Intelligence):

The use of machine learning and algorithms in textile production to optimize material selection, enhance precision, and reduce waste.

Blockchain Technology:

A decentralized digital ledger system used to track the supply chain of sustainable materials, ensuring transparency and ethical sourcing in the fashion industry.

Circular Economy:

A production model focused on minimizing waste and maximizing resource efficiency by recycling, repurposing, and extending the lifecycle of products.

Digital Textile Printing:

A sustainable printing method that eliminates toxic dyes, reduces water consumption, and allows mass customization with minimal environmental impact.

Enzyme:

A natural protein that speeds up chemical reactions in living things, like helping digest food or break down substances.

Enzyme-Based Finishing:

A bioengineering technique that replaces harsh chemical treatments in textile production, reducing water pollution and energy consumption.

IoT (Internet of Things):

The network of connected sensors and devices used in textile manufacturing to monitor efficiency, track materials, and minimize resource waste.

Microbial Textile Dyeing:

A dyeing method that utilizes bacteria-based pigments instead of synthetic dyes, reducing toxic dye waste and water consumption.

Nanotechnology (in Textiles):

The application of nanoscale coatings or fibers to improve fabric durability, stain resistance, and antibacterial properties without harmful chemicals.

RFID (Radio Frequency Identification):

A technology used to track textiles in real-time, reducing overproduction and ensuring supply chain transparency.

Authors & Researchers

Jordy Munarriz

Environmental Engineer with a master's degree in renewable energy and a specialization in sustainability. Researcher and writer, he combines his technical knowledge with his passion for environmental communication, addressing topics of ecological impact and sustainable solutions in the textile industry and beyond.

Lesia Tello

Biologist and researcher specializing in biochemistry, with a master’s degree in education. Passionate about scientific inquiry, she explores the complexities of life and the processes that sustain it. Her work focuses on the intersection of science, education, and communication, making scientific knowledge accessible and impactful.

Authors & Researchers

Authors & Researchers

Jordy Munarriz

Environmental Engineer with a master's degree in renewable energy and a specialization in sustainability. Researcher and writer, he combines his technical knowledge with his passion for environmental communication, addressing topics of ecological impact and sustainable solutions in the textile industry and beyond.

Lesia Tello

Biologist and researcher specializing in biochemistry, with a master’s degree in education. Passionate about scientific inquiry, she explores the complexities of life and the processes that sustain it. Her work focuses on the intersection of science, education, and communication, making scientific knowledge accessible and impactful.

References:

[1] Islam, M. M., Perry, P., & Gill, S. (2021). Mapping environmentally sustainable practices in textiles, apparel and fashion industries: a systematic literature review. Journal of Fashion Marketing and Management: An International Journal, 25(2), 331-353. https://www.emerald.com/insight/content/doi/10.1108/jfmm-07-2020-0130/full/html

[2] Nayak, R., Panwar, T., Grover, T., & Singh, A. (2024). Recent trends in sustainable clothing and textile manufacturing. In Sustainable Manufacturing Practices in the Textiles and Fashion Sector (pp. 75-93). Cham: Springer Nature Switzerland. https://link.springer.com/chapter/10.1007/978-3-031-51362-6_4

[3] Roy, R., Chavan, P. P., Rajeev, Y., Praveenraj, T., & Kolazhi, P. (2024). Sustainable manufacturing practices in textiles and fashion. In Sustainable Manufacturing Practices in the Textiles and Fashion Sector (pp. 1-22). Cham: Springer Nature Switzerland. https://doi.org/10.1007/978-3-031-51362-6

[4] Niinimäki, K., & Hassi, L. (2011). Emerging design strategies in sustainable production and consumption of textiles and clothing. Journal of cleaner production, 19(16), 1876-1883. https://doi.org/10.1016/j.jclepro.2011.04.020

Glossarykeywords

3D Knitting:

A seamless garment production technique that eliminates fabric waste by directly knitting entire pieces, reducing material consumption and improving efficiency.

AI (Artificial Intelligence):

The use of machine learning and algorithms in textile production to optimize material selection, enhance precision, and reduce waste.

Blockchain Technology:

A decentralized digital ledger system used to track the supply chain of sustainable materials, ensuring transparency and ethical sourcing in the fashion industry.

Circular Economy:

A production model focused on minimizing waste and maximizing resource efficiency by recycling, repurposing, and extending the lifecycle of products.

Digital Textile Printing:

A sustainable printing method that eliminates toxic dyes, reduces water consumption, and allows mass customization with minimal environmental impact.

Enzyme:

A natural protein that speeds up chemical reactions in living things, like helping digest food or break down substances.

Enzyme-Based Finishing:

A bioengineering technique that replaces harsh chemical treatments in textile production, reducing water pollution and energy consumption.

IoT (Internet of Things):

The network of connected sensors and devices used in textile manufacturing to monitor efficiency, track materials, and minimize resource waste.

Microbial Textile Dyeing:

A dyeing method that utilizes bacteria-based pigments instead of synthetic dyes, reducing toxic dye waste and water consumption.

Nanotechnology (in Textiles):

The application of nanoscale coatings or fibers to improve fabric durability, stain resistance, and antibacterial properties without harmful chemicals.

RFID (Radio Frequency Identification):

A technology used to track textiles in real-time, reducing overproduction and ensuring supply chain transparency.

References:

[1] Islam, M. M., Perry, P., & Gill, S. (2021). Mapping environmentally sustainable practices in textiles, apparel and fashion industries: a systematic literature review. Journal of Fashion Marketing and Management: An International Journal, 25(2), 331-353. https://www.emerald.com/insight/content/doi/10.1108/jfmm-07-2020-0130/full/html

[2] Nayak, R., Panwar, T., Grover, T., & Singh, A. (2024). Recent trends in sustainable clothing and textile manufacturing. In Sustainable Manufacturing Practices in the Textiles and Fashion Sector (pp. 75-93). Cham: Springer Nature Switzerland. https://link.springer.com/chapter/10.1007/978-3-031-51362-6_4

[3] Roy, R., Chavan, P. P., Rajeev, Y., Praveenraj, T., & Kolazhi, P. (2024). Sustainable manufacturing practices in textiles and fashion. In Sustainable Manufacturing Practices in the Textiles and Fashion Sector (pp. 1-22). Cham: Springer Nature Switzerland. https://doi.org/10.1007/978-3-031-51362-6

[4] Niinimäki, K., & Hassi, L. (2011). Emerging design strategies in sustainable production and consumption of textiles and clothing. Journal of cleaner production, 19(16), 1876-1883. https://doi.org/10.1016/j.jclepro.2011.04.020

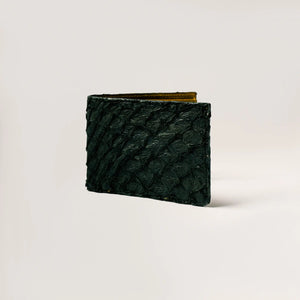

You don't have to put all the weight on your shoulders. Every action counts. At AYA, we fight microplastic pollution by making a 100% plastic-free catalog.

Visit Our Shop →You May Also Like to Read...

The Truth About Recycled Polyester in Fashion

Discover the hidden costs of recycled polyester. Learn why rPET isn't as sustainable as it seems and what real circular alternatives look like.

Synthetic Fabrics vs. Organic Cotton: Impact on Skin Health

Discover how polyester and other synthetic fabrics can irritate your skin and why organic cotton, especially Pima cotton, is a healthier and safer choice for sensitive skin.

What Peru Whispers: Organic Pima Cotton Grown with Tradition and Care

In the quiet corners of Peru, organic pima cotton is grown with respect for the land. A luxurious, timeless textile waiting to be discovered.

Why Sustainable Fashion Shouldn’t Be Fast Fashion

Recycled materials and green labels won’t fix fast fashion. Discover why real sustainability means slowing down.